您想增加產量嗎?您想增加利潤嗎?

介紹

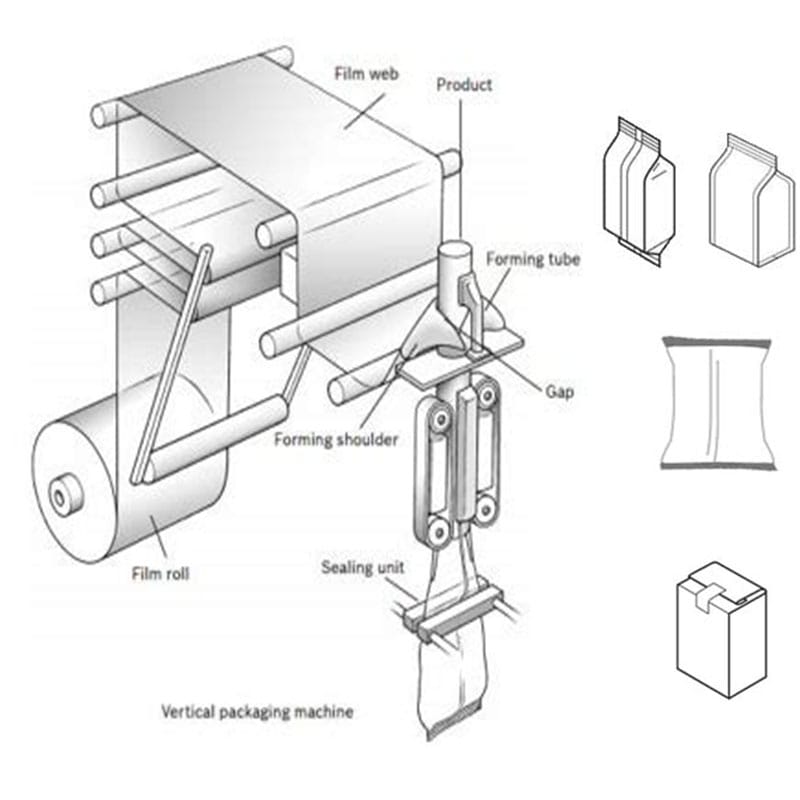

直立式套袋機也稱為垂直填充密封 (VFFS) 機,是廣泛應用於各個行業的自動化包裝系統,用於將產品有效地包裝在軟袋或小袋中。這些機器的工作原理是:將一卷薄膜形成袋子,填充產品,然後密封,所有過程都是垂直方向的。

立式套袋機的工作原理

垂直套袋機的工作原理由幾個步驟組成:首先,以一卷包裝材料(通常是聚乙烯或聚丙烯薄膜)開始製袋,然後透過滾筒垂直引導薄膜形成連續的管狀結構,縱向密封。在填充階段,將產品定量裝入袋子中。

直立式裝袋機具有多種功能,例如能夠添加日期/批次代碼、用於打開的撕裂縫、用於懸掛展示的打孔等。包裝時間。

立式套袋機的類型

直立式套袋機 通常設計得非常靈活,可以在不同的袋子尺寸之間快速切換,無需工具即可在幾分鐘內完成。此類機器的耐用性也得到了嚴格清潔程序的保證,並提供不銹鋼或可清洗選項

常見的立式包裝機有幾種。

立式小袋包裝機

專為小型一次性包裝(例如糖、番茄醬)而設計。

直立式棒狀包裝機

為即溶咖啡等單份產品製作細長包裝。

預製袋包裝機

給袋包裝機通常用作立式包裝機的替代品。

立式套袋機的應用

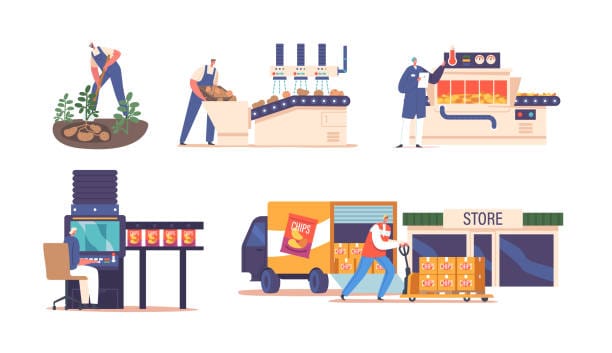

食品飲料業

據Data Bridge Market Research稱,食品和飲料行業對立式裝袋機的需求不斷增長,這很大程度上歸功於其在包裝多功能性和生產力方面的優勢。立式裝袋機能夠處理多種產品形式,從零食和糖果到冷凍食品和粉狀飲料,其高精度填充和密封技術可確保新鮮度和保質期,同時提高包裝的吸引力和適銷性。

醫藥行業

在製藥業,立式裝袋機用於包裝藥品、保健品和醫療用品,確保產品的安全密封和劑量控制。同時,藥品的穩定性和有效期限極為重要,立式裝袋機的高精度填充功能保證了封口技術。另外,立式裝袋機可以適應不同的包裝材料,包括防潮和氧化保護層,這對於敏感藥品的長期儲存和運輸尤其重要。

化妝品產業

大多數化妝品公司都利用這些機器來包裝粉底、口紅和護膚霜等粉末、液體和霜狀產品。立式裝袋機可提供精確的填充水平和有吸引力的包裝設計,這對於提升品牌形象和吸引消費者至關重要。同時,直立式裝袋機的密封技術保證了有效成分的新鮮度和穩定性,並延長了產品的保質期。

化工

立式套袋機也廣泛應用於化學產品的包裝,包括農藥、殺蟲劑、塗料等。這些產品通常需要精確的劑量控制和安全密封以防止洩漏和污染。立式裝袋機能夠適應各種包裝材料,包括耐腐蝕和耐化學材料,確保產品的安全儲存和運輸。

其他行業

除了上述產業外,立式套袋機也用於農業、建築材料、電子產品的包裝。在農業中,它們被用來包裝種子和肥料;在建築業中,用於包裝乾燥劑和防水材料;在電子領域,用於包裝小型元件和配件。這些應用展示了立式裝袋機的多功能性和適應性,能夠滿足不同產業對包裝效率和品質的需求。

技術開發與創新

自動化和機器人技術與升級相結合

隨著工業自動化的不斷進步,立式套袋機的自動化水準顯著提高。現代立式裝袋機整合了自動化零件供應、裝袋和機器控制系統等先進的自動化技術,減少了體力勞動的需求並提高了產能。協作機器人的使用在需要精確性和靈活性的任務中發揮重要作用,可以釋放人力資源來處理更複雜的任務。

情報和數據分析

智慧控制和數據分析是推動立式裝袋機效能優化和減少停機時間的關鍵技術。嵌入式感測器和人工智慧演算法監控機器參數,自動偵測異常並調整設定以確保最佳運作。即時數據分析可以深入了解機器性能、維護要求和包裝效率,使操作員能夠做出明智的決策並降低營運成本。

永續發展和綠色包裝

永續性越來越受到消費者和企業的關注。立式裝袋機越來越多地採用可持續的做法和材料,以盡量減少對環境的影響。可生物降解和可堆肥的包裝薄膜、可回收材料和節能設計變得越來越普遍,支持循環經濟並減少浪費。

靈活性和客製化包裝

在快速變化的市場中,靈活性和客製化至關重要。立式裝袋機旨在處理更廣泛的產品和包裝形式。快速轉換系統、多個袋頭和可調節設定使製造商能夠適應不同的生產需求,滿足客戶客製化包裝的需求。

新材料袋設計與處理

立式裝袋機的未來也將專注於改進袋子設計和處理能力。先進的薄膜密封技術將製造出更堅固、更耐用的袋子,減少產品損壞並延長保質期。自動袋定位和處理系統可確保精確放置和對齊,從而提高整體包裝品質和效率。

預測性維護和遠端監控

預測性維護和遠端監控對於最大限度地減少機器停機時間和確保連續運作至關重要。先進的演算法可以預測設備故障並觸發及時的維護任務,從而延長機器壽命並減少意外中斷。遠端監控功能使製造商能夠遠端存取機器資料、排除故障和更新,從而最大限度地減少停機時間並提高生產率。

結論

立式裝袋機已成為一項關鍵技術,改變了從食品和藥品到化妝品和化學品等多個行業的包裝。它們的演變反映了現代製造業技術創新、永續性和適應性的更廣泛趨勢。

對於尋求提高生產效率、減少浪費並在快速發展的市場中保持競爭力的企業來說,投資先進的立式裝袋技術不再只是一種選擇,而是一種策略需求。

關注Lintyco,聯絡我們了解更多!